Most of us know that, “BEEEEP” from your car, followed by that little amber light, that looks like an engine with a lightening bolt in it. Or maybe even the phrase, “Emissions Workshop” showing in the instrument cluster. But do you know what it means when your vehicles check engine light comes on? Understanding what your check engine light means can save both headache and wallet-ache! Before I get into what a check engine light means, let’s talk about what it is, and why we even have it.

All cars from model year 1996 and newer are set to a basic standard. That standard is known as O.B.D II, short for On Board diagnostic second generation. It basically says that all cars will meet a certain standard when it comes to diagnostics, they include

- A standard connector to hook up a scan tool. This is so all shops can gather the same information.

- Standard(ish) location for the connector, called a Data Link Connector or DLC for short

- Standard codes, basically if a VW has a failed sensor, and a Honda has a failed sensor, they must use the same code to describe the fault, more on that later.

- There are more standards, but they have to do with communication rates, and more things that do not really matter.

- Also, the light itself has a standard(ish) look to it.

When your check engine light comes on, it means the cars engine computer sees an issue. The issue can be anything from a loose gas cap, to engine timing being wrong, or some crazy wiring issues. I could go on for days and days about all the ways that the check engine light can come on.

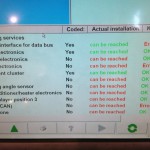

When you bring your car to have the codes checked, I would hook up a diagnostic tool. I generally prefer a VAS 5051B. That is the big boy of VW scan tools. I find it to be far more reliable than the other scan tools we have. The information that I get is show like this.

P0420, Catalyst efficiency below threshold.

The “P” code is used to determine what system the fault is. P0420, the P is for power train, the 0 means that a Fuel and Air Metering and Auxiliary Emission Controls fault exists, and the last 3 digits give a more specific system of failure.

There are 3 states of your check engine light.

OFF

If your check engine light is “OFF”, you generally have nothing to worry about. There might be an issue, but it has not happened enough times to set the light. Most issues take 2 failures in a row to turn the light on.

ON

If the light is “ON”, you have an system in your engine or transmission that is having an issue. If your car is driving normal, get it to a service station when you can. I DO NOT recommend waiting for an extended period of time. The longer you wait, the more likely you are to have more issues.

FLASHING

Ok, this one is pretty serious, if the light is “FLASHING”, you need to STOP driving and have the car towed to a service station(I prefer the dealer of course). When the light is flashing, your vehicle is mis-firing. That means the air and fuel is not being used properly. This will cause damage to the vehicle emissions system, and that is expensive.

Some quick advise, if your check engine light comes on, check your gas cap first. It is free, and might eliminate the hassle of bringing your car in for service. Also, if your light is just “ON” and the car runs fine, don’t panic. Just get it fixed soon.

Don’t forget that we have are on facebook. Also, if you hate check engine lights, just click one of the share buttons below, it will eliminate them forever~well, not really but it is worth a shot right 😉