Happy Thursday boys and girls. I can’t believe that today is the last day of July. It is crazy when you realize how fast the year has gone by. Okay, enough reminiscing, it is time for Shop Shots!

This may not look like something out of the ordinary, but it is. This engine was delivered to us a few days ago. When they took it off the truck I was shocked. Shocked because I had no idea what the heck type of engine it was. I have seen plenty of VW engines, and this didn’t look anything like that. That is because it is NOT a VW engine. It is for a dang Routan.

This may not look like something out of the ordinary, but it is. This engine was delivered to us a few days ago. When they took it off the truck I was shocked. Shocked because I had no idea what the heck type of engine it was. I have seen plenty of VW engines, and this didn’t look anything like that. That is because it is NOT a VW engine. It is for a dang Routan.

I got some of the story on why we are replacing a Routan engine with a junkyard engine. It seems that a customer drove through water high enough to pull water into the engine. I don’t know why people do that. It should be interesting to see this Routan get an engine replacement. I will keep everyone updated when the repair is done. Maybe there will be some cool pictures of the damage.

This is a much less rare thing. You are looking at a B7 Passat VR6. This car had some type fault for a Knock sensor. There is a Tech Tip, or a TSB for this issue. The repair is replacing the engine room harness. There are probably about 30 connectors on that harness. Replacing an engine harness can be a big task depending on the engine. I talked to the tech working on this car, he said it was one of the easier ones.

This is a much less rare thing. You are looking at a B7 Passat VR6. This car had some type fault for a Knock sensor. There is a Tech Tip, or a TSB for this issue. The repair is replacing the engine room harness. There are probably about 30 connectors on that harness. Replacing an engine harness can be a big task depending on the engine. I talked to the tech working on this car, he said it was one of the easier ones.

This last one is a good one. This is a steering knuckle from a Touareg. The holes are where the brake caliper bolts on. One of the techs in the shop was replacing the brakes on this Touareg. When he put the bolts back in, the threads got damaged. We retapped the hole, and cleaned up the bolts. Even after that the job went sideways and ruined the treads.

This last one is a good one. This is a steering knuckle from a Touareg. The holes are where the brake caliper bolts on. One of the techs in the shop was replacing the brakes on this Touareg. When he put the bolts back in, the threads got damaged. We retapped the hole, and cleaned up the bolts. Even after that the job went sideways and ruined the treads.

Replacing the knuckle is expensive, and the machine shop didn’t have a heli-coil that size. The solution for this comes in the form of a Time Sert. These things are amazing. You basically drill a bigger hole, and thread a sleeve into the hole. The picture on the left is the repaired bolt hole, the one on the right is the good one. It is a great solution for a job that goes bad.

That does it for another volume of Shop Shots. As always I hope you have enjoyed the pictures and little stories behind them.

The first picture come to us by way of a complete hack mechanic. You are looking at the the cowl panel of a VW Beetle. That is the trim right at the bottom of the windshield. You will notice that someone has drilled a hole in the trim. Talk about a hack move.

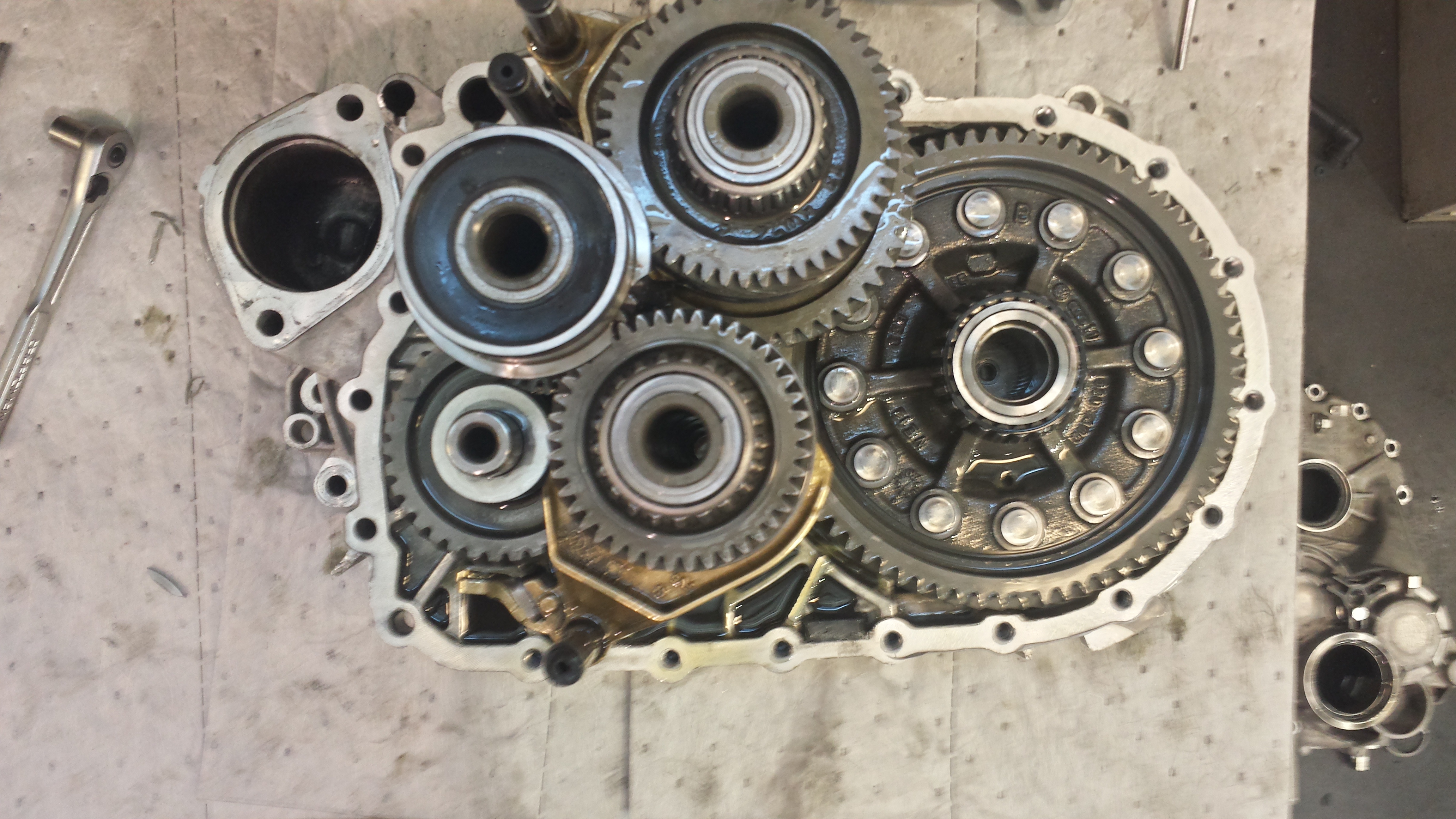

The first picture come to us by way of a complete hack mechanic. You are looking at the the cowl panel of a VW Beetle. That is the trim right at the bottom of the windshield. You will notice that someone has drilled a hole in the trim. Talk about a hack move. This type of picture makes me feel a bit like a curios kid. When ever I see an engine or a transmission taken apart, I get excited. Especially when I am not the one taking it apart. 😉 Not that I mind doing this type of work, it just doesn’t pay that well.

This type of picture makes me feel a bit like a curios kid. When ever I see an engine or a transmission taken apart, I get excited. Especially when I am not the one taking it apart. 😉 Not that I mind doing this type of work, it just doesn’t pay that well. I feel like this is the things that mechanics have nightmares about. You are looking at a wiring harness in a 2014 Tiguan. The customer had about 400 miles on their car. They brought it in because the 12v outlet wouldn’t work. When I got the car the fuse was blown. Each time a new fuse was installed, it would pop. That could mean the power wire was shorted to ground(which is the brown wire in the picture).

I feel like this is the things that mechanics have nightmares about. You are looking at a wiring harness in a 2014 Tiguan. The customer had about 400 miles on their car. They brought it in because the 12v outlet wouldn’t work. When I got the car the fuse was blown. Each time a new fuse was installed, it would pop. That could mean the power wire was shorted to ground(which is the brown wire in the picture).

The story behind this picture could be a post all by itself. It is the typical “You messed up my car” story, that is just a matter of a problem showing itself at a bad time.

The story behind this picture could be a post all by itself. It is the typical “You messed up my car” story, that is just a matter of a problem showing itself at a bad time. Next up in the “this is a total bummer” series, a failed clutch. Well it was not really the clutch that failed, it was the release bearing. The bearing is the part that pushes on the pressure plate when you push the clutch pedal.

Next up in the “this is a total bummer” series, a failed clutch. Well it was not really the clutch that failed, it was the release bearing. The bearing is the part that pushes on the pressure plate when you push the clutch pedal. I feel like this is a picture that I have to post way too much. The story is about the same. Car comes in with the oil light on. We check it out and find that the pickup tube is clogged. We spend a few hours cleaning the crud from the bottom of the oil pan.

I feel like this is a picture that I have to post way too much. The story is about the same. Car comes in with the oil light on. We check it out and find that the pickup tube is clogged. We spend a few hours cleaning the crud from the bottom of the oil pan.