It is no secret that car technology is advancing at an insane pace. In the almost 9 years I have been working on cars I have seen some pretty awesome advances. A perfect way to show how far we have come is something as simple as a light bulb.

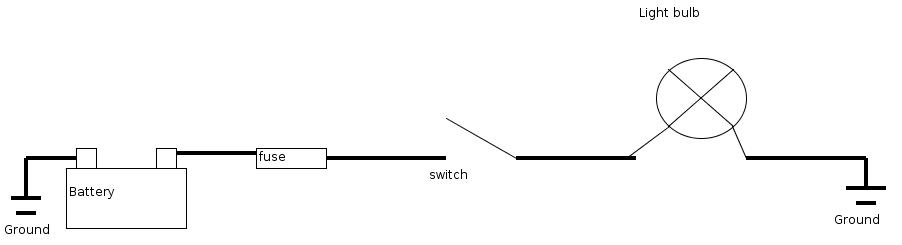

When I started with VW the 2004 model was the latest and greatest. Even in 2004 we had some pretty smart cars. But the light bulb was still a pretty simple setup. Here is basically what it took to light a bulb in your car in 2004.

Basically you just had a few parts.

Basically you just had a few parts.

- Battery. This will provide power to the light

- A fuse. This will protect the circuit from damage

- A switch to control the light

- The light itself. Hard to talk about lighting a light bulb, with out the light bulb right.

Power will flow through the fuse, to the switch then from the switch to the bulb, and light the bulb. BTW I am not interested in debating power flow from power to ground pr ground to power for this post. Lets save that for another day. 😀 This is a pretty simple setup. Problems could be found by using a simple test light.

Oh how far we have come. Today we have a much different way to light the same bulb.

Now we have added a few parts.

Now we have added a few parts.

- Battery, pretty much the heart of the cars electrical system

- Switch. you still have to still have to turn the light on.

- Bulb, still need the bulb to light the bulb

- Module, now the power, and ground for the light are controlled, and monitored by a module. the module acts as a fuse as well

- Diagnostic connector. This is how we monitor the bulb

As you can see lighting the bulb seems to be much more complicated now. We have added modules and diagnostic ports. Why the heck would they do that? Is it because VW likes to over engineer things? Nah, it’s all about the driver. By using a module(that will talk to other modules) we can alert the driver when a bulb is out. You can even get super awesome and have lights turn themselves on.

The diagnostic approach is a little different. Now mechanics can use a scan tool to diagnose an issue with a light. I can use that scan tool to activate the light to test the activation side of the circuit. I can also use the scan tool to monitor the position of the switch. I can watch the readings change from “ON” to “OFF” when I push the button.

I have mixed feelings about both setups. The old way requires taking things apart to test. Usually you can be sure of the issue. With the new way, you can watch what is happening on a scan tool, but you add the “magic box”. You can’t know for sure what is happening inside there. Sometimes that requires a roll of the diagnostic dice. I guess it boils down to knowing the system. It doesn’t really matter how you feel about it, you still have to know it.

What do you guys think? Is throwing a bunch more electronics in a car a good thing? Is giving the mechanic a “hands off” way to diagnose a car the wave of the future? Are you an old school test light fan? Post it up! BTW~ This was my first attempt at making a wiring diagram online. I don’t think they came out that bad. Not great, but not bad…

Remember, you can join up on the mail list. It is super easy and you will not miss a post. I know I asked a lot of questions of everyone today, but I have one more. If you were part of an elite group what would you want to be called? I am thinking of naming the email list. Something like the “Humble Club”. Any ideas? You guys seem to always come up with really awesome stuff.

If you didn’t understand anything about the wiring diagrams I posted, its cool, just share them with your friends. Oh, and don’t feel bad, there are a lot of mechanics that don’t understand wiring diagrams either.